Aluminum Alloy Vibration Bowl Feeder Metal Parts Automatic

Vibrating Feeder

1 . Descriptions:

Vibratory bowl feeders are reliable devices used in automation and

material handling to efficiently supply small parts and sort bulk

items. They use vibrations to handle and orient bulk materials

accurately during assembly processes.

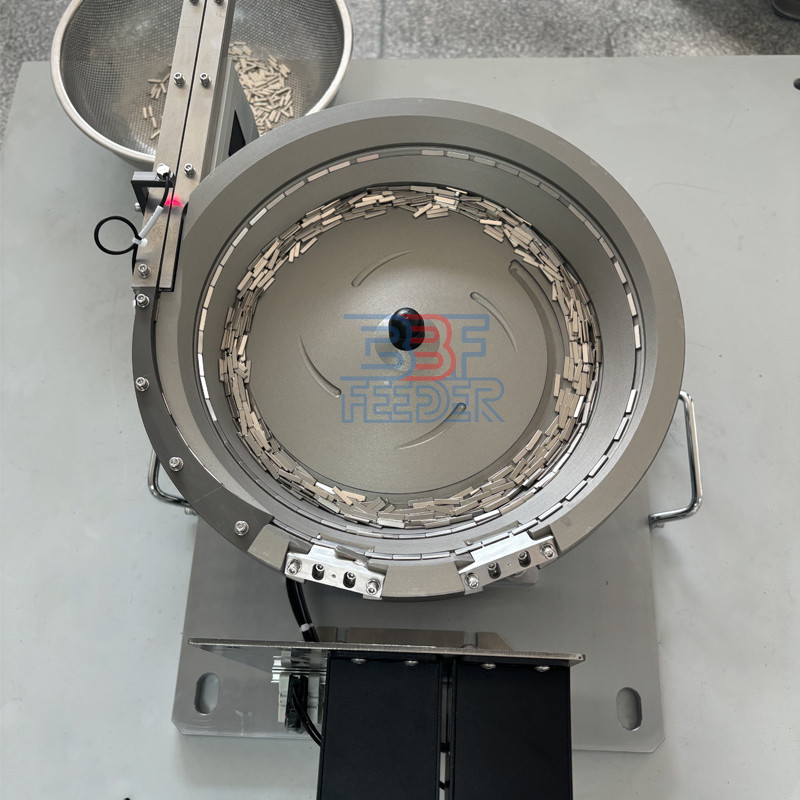

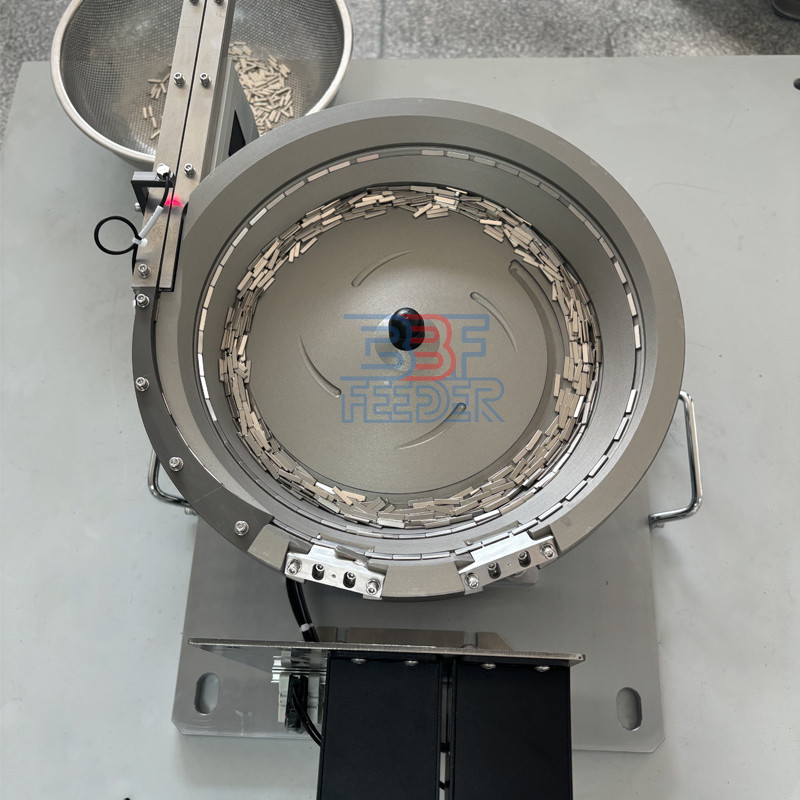

These feeders typically consist of a bowl placed on a vertically

moving base. By utilizing vibrations, they enable the upward

movement of small parts along the bowl tooling. Despite their

compact size, bowl feeders demonstrate exceptional capabilities in

arranging, selecting, feeding, and sorting parts, making them a

cost-effective solution. Their performance is evaluated based on

factors such as output rate, part orientation, and floor space

utilization. Some bowl feeders can achieve impressive output rates

of up to 1600 parts per minute.

Bowl feeders play a vital role across diverse industries, including

automotive production, chemical processing, electronics

manufacturing, food and beverage processing, foundry work, glass

making, packaging, pharmaceuticals, railroading, and recycling. By

efficiently organizing and segregating bulk parts, they enhance

manufacturing efficiency and reduce labor requirements.

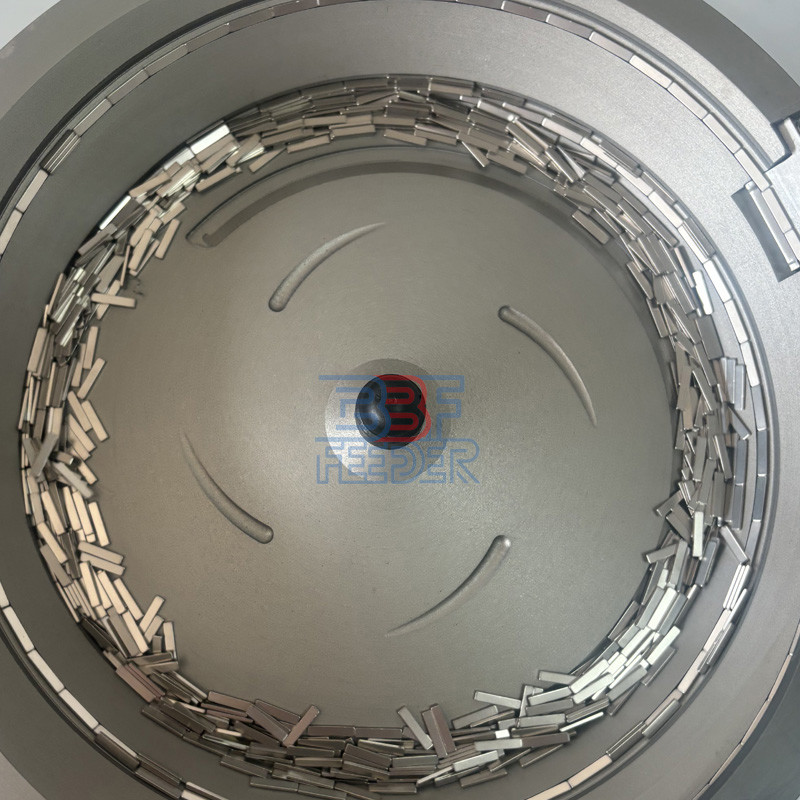

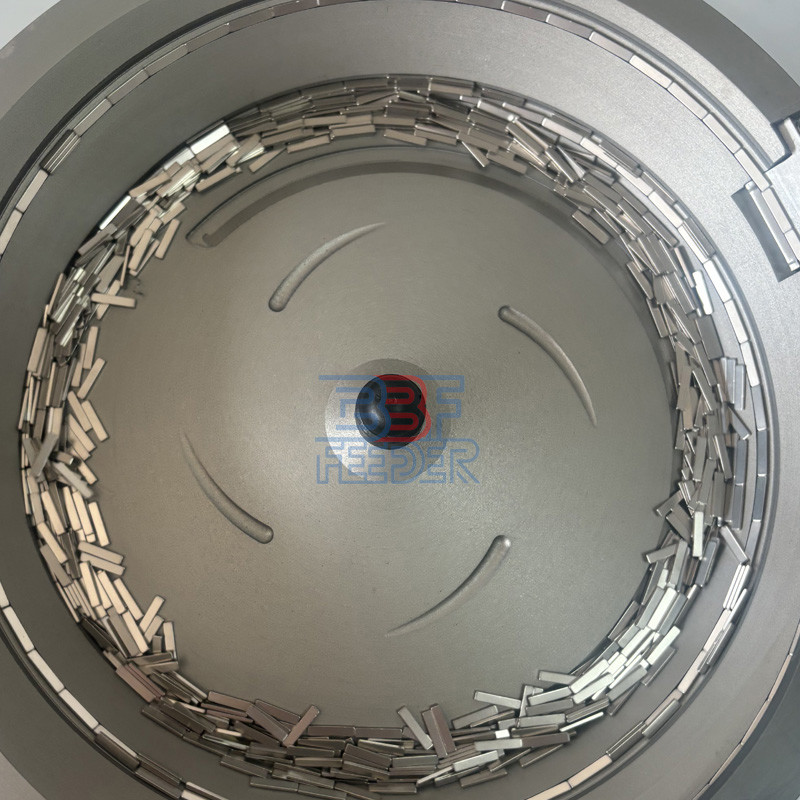

During the design of a bowl for a bowl feeder, careful attention is

paid to ensure that the parts are guided along the inner and outer

circumference of the bowl. Factors such as track length, shape, and

size are meticulously considered to meet specific feeding

requirements, including part orientation and direction. In certain

cases, a special coating may be applied to facilitate the feeding

process.

2 . Specifications:

| Product name | Vibratory Bowl Feeder |

| Material | Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers'

Requirements |

| Controller | CUH,Sanki,Sinfonia,REO,Afag |

| Voltage | 220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power | 300W/500W/1000W/1500W/2000W |

Color | Green or Based on Customers' Requirement |

| Speed | Based on Customers Requirements |

| Warranty | 2 Years |

| Certification | CE, ISO9001, ROHS |

| Lead Time | 3 Working Weeks |

3 . Vibratory Bowl Feeder Noise Reduction :

Vibratory bowl feeders are extensively used in various industries

to load and feed small parts for assembly or packaging purposes.

These feeders employ vibrations in a spiral-shaped bowl with

narrowing and sloping feeding lanes, enabling the individual

feeding of parts. However, it is crucial to address noise control

and ensure operator accessibility when utilizing these feeders.

To mitigate noise, preventing it from reaching the operator is

essential. Treating the bowl itself can disrupt its operation, so

noise reduction equipment should effectively block the noise path.

Additionally, the solution should facilitate easy maintenance

access and uninterrupted feeding. An optimal enclosure should

feature clear sound barrier windows on all sides, enabling visual

inspection.

One potential solution is the implementation of a sound curtain

enclosure. This enclosure consists of four sides and an open top,

incorporating a double roller track that allows panels to slide for

maintenance purposes. Clear sound barrier windows should be

integrated into all sides of the enclosure to enable visual

inspection.

Another alternative is a modular steel sound enclosure, comprising

four sides and a roof. This enclosure is equipped with doors for

feeder access and removable panels for convenient maintenance.

Windows on all sides provide the capability for visual inspection,

while 2" or 4" thick acoustical panels effectively reduce noise.

4 . More Pictures: